Application of metallographic microscope in metallographic analysis

Release time:Release time:2024 - 07 - 12

The microstructure of the material determines the performance of the material, metallographic analysis is one of the important means to study the microstructure and composition of the material.

The use of metallographic microscope in specially prepared specimens on the magnification of 100 ~ 1500 times, through the metallographic photographs can be visual characterization of the organization of the material constituents, the material phase, grain, inclusions, etc., at the same time, the metallographic analysis is also an evaluation of the excellence of the material process and to find the cause of failure and defects of an effective means.

Raw material inspection

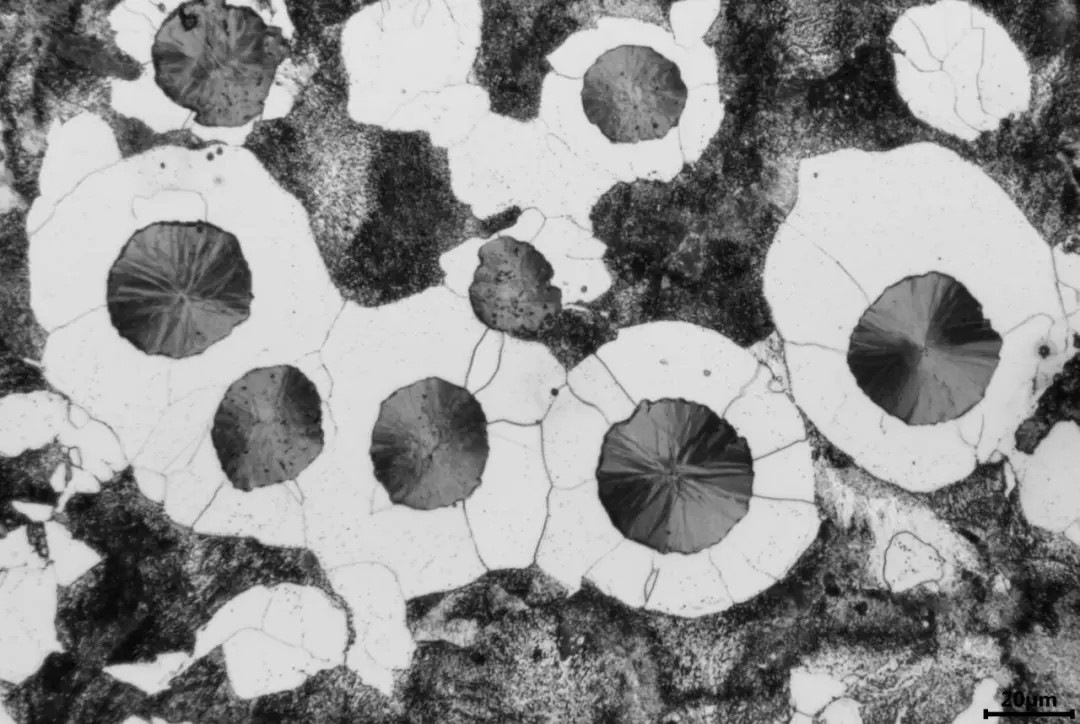

Check the metallurgical quality of raw materials; check the casting of casting materials for casting looseness, porosity, slag organization uniformity; check the surface decarburization, overheating, overcooking, cracking and deformation of forging parts.

▲ Ordinary cast iron

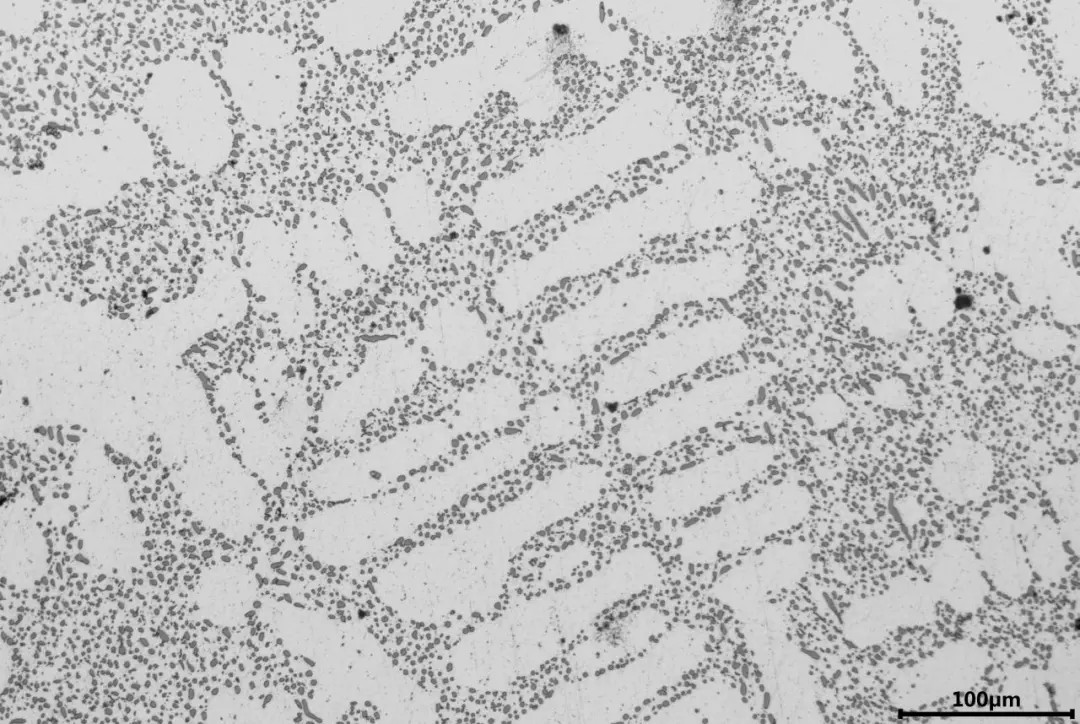

▲ Common non-ferrous metals

Quality control during production

Metallographic analysis can provide the basis for adjusting processes and modifying process parameters to guide production.

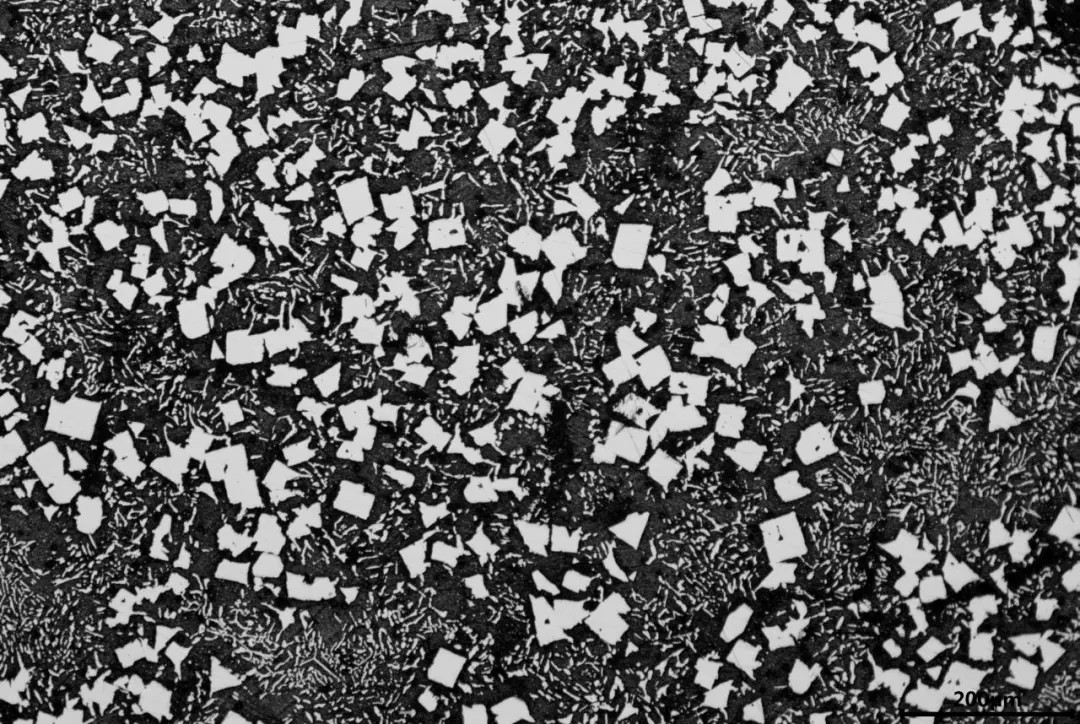

▲ Heat-treated carbon steel

▲ Common Thermal Processing Defects Organization

Product quality inspection

Some mechanical parts or products in addition to the requirements of mechanical properties, physical properties indicators, but also requires microstructure parameters as a quality assessment of technical indicators.

▲ Binary and ternary alloy organization

SOPTOP has a variety of orthogonal and inverted metallographic microscopes that can be used to identify and analyze the organization of various metals and alloys, which are widely used in factories or laboratories for the identification of casting quality, inspection of raw materials, or the study and analysis of the metallographic organization of materials after treatment.

Return list